Bitumen

Bitumen is a sticky, black, and highly viscous liquid or semi-solid form of petroleum. It may be found in natural deposits or may be a refined product, and is classed as a pitch. The primary use (70%) of asphalt is in road construction, where it is used as the glue or binder mixed with aggregate particles to create asphalt concrete. Its other main uses are for bituminous waterproofing products, including production of roofing felt and for sealing flat roofs.

Viscosity Grades

Bitumen is graded based on absolute viscosity at 60 ºC or kinematic viscosity at 135 ºC. The SI physical unit of dynamic viscosity is Poise and kinematic viscosity is expressed in Centistokes. Pure bitumen has been graded based on AASHTO-M226 and ASTM-D3381 standards.

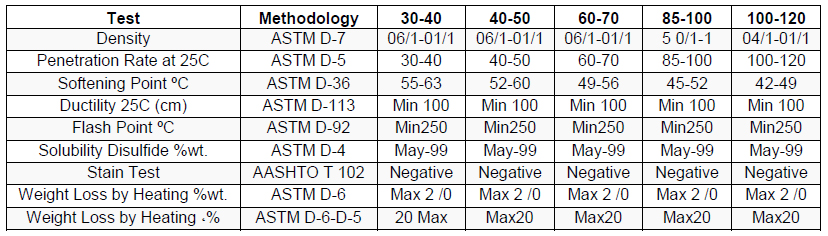

Penetrations Grades

Penetration-grade bitumen is mainly used in road surfacing. Bitumen with lower penetration grade is used in the regions with warm climate while higher penetration grade is used in colder weather. Our company is capable to supply different grades of road surfacing bitumen in compliance with national and international standards.

Polymer modified bitumen

Polymers represent the most important family of bitumen modifiers. Depending on the type of polymer, the specifications of bitumen under different temperatures change. For example, polymers make bitumen resistant to heating cracks. Modifying the bitumen specifications boosts the quality of the product and increases its longevity. As a result, the costs of preservation will decline sharply. The daily growing development of polymers and their diversity have caused widespread research on these materials across the world. SBS is one of the best modifying polymers with both thermoplastic and rubber specifications. Although polymer modified bitumen costs higher than pure bitumen, they are considered to be more economical because of economic benefits of lower costs of road repairs. The polymers widely used for modifying bitumen are SBS, EVA, APP, LDPE, LLDE, HDPE, SBR, SEBS and SIS.

Emulsions Bitumen emulsions are two-phased systems consisting of bitumen, water, and one or more additives to assist in formation and stabilization and to modify the properties of the emulsion. Bitumen emulsions can be divided into four classes. The first two are, by far, the most widely used:

- Cationic emulsions

- Anionic emulsions

- Non-ionic emulsions

- Clay-stabilized emulsions

Bitumen emulsions are divided into three categories in terms of setting:

- Rapid-setting (RS)

- Medium-setting (MS)

- Slow-setting (SS)

Oxidized bitumen

Oxidized bitumen is mainly used for industrial purposes, such as roof insulation, flooring, industrial mastics, pipe coating, and paints. Oxidized bitumen is categorized based on softening points and penetration rate. For example, oxidized bitumen 85/40 is a type of bitumen whose softening point is 85±5 degrees Centigrade and its penetration rate is 40±5 dmm. Oxidized bitumen is also expected to make up for weight loss under heat. The softening point in oxidized bitumen is much higher than in regular bitumen, causing lower thermal sensitivity. The penetration index (PI) in oxidized bitumen is higher than in road construction bitumen (8>PI>2) because the letter has a gel-like structure due to asphalt accumulation. Cutback Bitumen Bitumen is ‘cutback’ by adding controlled amounts of petroleum distillates, such as kerosene. This is done to reduce the viscosity of the bitumen temporarily so it can penetrate pavements more effectively or to allow spraying at temperatures that are too cold for successful sprayed sealing with neat bitumen. The materials used to cutback bitumen will evaporate after application to leave the remaining material similar in hardness to the original bitumen. Cutback bitumen is used when there is limited access to heating equipment and bitumen may be cooled throughout working. This type of bitumen is used in road operations for surfacing and pavement. Medium-Curing (MC) bitumen is achieved from solving pure bitumen into kerosene. Cutback bitumen is classified based on viscosity grade. It is divided into three categories: Rapid-Curing (RC): The cutback bitumen is known as rapid-curing (RC) if the bitumen is solved in gasoline. The reason is that evaporation occurs quickly and the bitumen is deposited. Medium-Curing (MC): MC cutbacks are prepared by solving bitumen in kerosene which evaporates more slowly than gasoline. Slow-Curing (SC): Slow-curing cutback may be achieved from solving bitumen in gasoil or fuel oil or directly from distillation of crude oil.